What Are Graphene Coatings?

Graphene and ceramic coatings are treatments used on vehicles during a full auto detail. These coatings are meant to protect your vehicle.

In this article, we’ll go through this treatment method in detail and answer common questions around this topic.

Graphene Coatings Guide

- Where do Graphene Coatings Come From?

- Why Are Graphene Coatings Important to My Vehicle?

- Which Is Better: Graphene Coating vs. Ceramic Coating?

- Benefits of Graphene Coatings

Where Do Graphene Coatings Come From?

Before we talk about why graphene coatings are important for your vehicle and which coatings are the best ones to use, we need to give you a little history about this property and where it came from.

Graphene, as we are speaking of it, was first discovered in 2004. Andre Geim and Konstantin Novoselov won the Nobel Prize in 2010 for their work on graphene.[1] Graphene turned out to have remarkable properties – much more than we ever thought.

“As a conductor of electricity, it performs as well as copper. As a conductor of heat, it outperforms all other known materials. It is almost completely transparent, yet so dense that not even helium, the smallest gas atom, can pass through it.”

Graphene has far-reaching implications for our technology and society moving forward. You may be thinking that’s great, but how do graphene coatings benefit my car? Well, let’s dig a little deeper into the science as it relates to the automotive world.

It is believed that on its own graphene cannot form a proper coating. Graphene in its pure form is “chemically inert and non-reactive.”[3] Many auto detailers know this about graphene and immediately exclaim that all graphene products are fake. However, it is important to look at what companies are actually claiming. Almost none are claiming a pure graphene coating, for a number of reasons:

1) It may or may not be scientifically possible, and

2) If it was, it would be astronomically expensive.

Rather, what companies are promoting are graphene oxide coatings. Okay, what’s the difference?

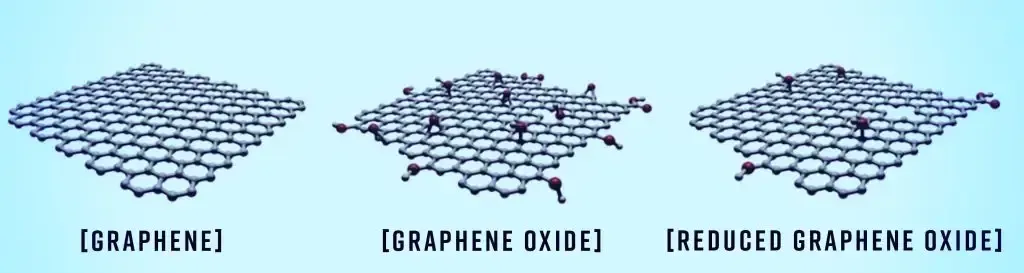

First, oxygen is added to graphene. That is going to yield graphene oxide. Technically speaking, it is not simply graphene oxide that is applied to your vehicle. There is a further necessary step. The elements that we do not want in this formulation, companies remove. After that they add in hydroxy molecules as well as other more beneficial elements.[4] Why do this? Because the hydroxy molecules are going to act like Velcro and stick extremely well to your clearcoat.

So, we have now gone from pure graphene (G) to graphene oxide (GO) to reduced graphene oxide (RGO). This reduced graphene oxide is what actually goes on your vehicle.

Imagine our graphene coatings are like bricks, something that is very strong and durable.[5] However, bricks alone are not sufficient to build a steady structure.

Think about a stack of bricks on top of each other. Yes durable, but a child could easily walk up and push over a pile of bricks and the whole thing would come tumbling down. Now, input the ceramic and hydroxy molecules into the equation. These are going to function as our mortar for the bricks. These act as the glue that holds the bricks in place and allows for the creation of a strong steady structure. This is why many of the products that you see are labelled graphene ceramic coating. It is not necessarily an entirely new product. What it is is an evolution of the ceramic coating that the car detailing world has come to know and love.

Why Are Graphene Coatings Important to My Vehicle?

The properties that make up graphene coatings create an effective coating to protect your vehicle from a number of things. Graphene coatings will:

- Reduce water spotting

- Increase durability

- Offer higher water contact angle (more hydrophobic)

- Increase hardness

- Offer same glossy mirror-like finish that ceramic coatings do

Which Is Better: Graphene Coating vs. Ceramic Coating?

If you are a car enthusiast, you may know about ceramic coatings and wonder if graphene coatings are even necessary.

Why go through all the trouble for this new technology? Why not stick with ceramic coatings? After all, it’s not like ceramic coatings were performing poorly. Certainly not! But graphene coatings actually have the ability to amplify all of the benefits of ceramic coatings, offering you more in return.

Are Graphene Coatings or Ceramic Coatings Better?

Ceramic Coatings

PROS

- Relatively new technology

- 1 – 5 years durability & protection

CONS

GRAPHENE Coatings

PROS

- Newer than ceramic coatings

- 5 – 10 years durability & protection

- Adheres better to surfaces

- Resists water spotting by 80 to 95%

- Offers high water contact angle

- Hard but flexible

- Glossy, mirror-like finish

CONS

- Unknown

Benefits of Graphene Coatings

How Does It Resist Water Spotting?

There are many receptor sites on ceramic coatings. If water adheres to one of these sites and is then bakes by the sun, it will leave behind deposits of minerals that were in the water. These become maddingly difficult to remove because the water spot has now cured with your coating. It is a part of the coating that is supposed to last years. Obviously, no one wants water spots on their vehicle, especially ones that may be there for years to come.

You could always put a sacrificial topper layer on your coating to protect from these water spots, but that does create another step in the process and adds to the overall cost of the job.

How do graphene-based coatings solve this? Well, recall that companies added hydroxy molecules to the formula to make the coating better adhere to the surface. While a traditional ceramic coating may have thousands of these receptor sites that allow water to attach, graphene-based coatings have relatively few of these receptive sites. So, less sites equals a far less chance of water spotting. Note that graphene coatings will not completely eliminate water spotting completely rather it will dramatically reduce it. Studies have shown a reduction on average between 80 to 95%.[6]

What Is a High Water Contact Angle?

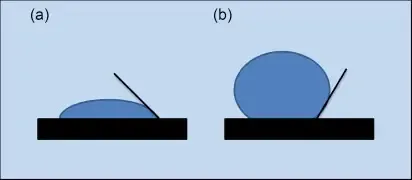

“When a drop of water is placed on a solid, it will spread on the surface based on the intermolecular interactions between the solid and the liquid.”[7] If the contact angle is above 90 degrees, then that particular surface would be labelled as hydrophobic. Below is a graphic to illustrate the difference.

Image (a) has a very low water contact angle whereas image (b) has a very high water contact angle. As we have talked about in other blogs hydrophobic properties are extremely beneficial when it comes to our vehicles. Now traditional ceramic coatings usually have a water contact angle of around 100 degrees. This is what creates those beads you see as it rains or your wash your vehicle. Now because of the nature of graphene-based coatings this has been increased to around 115 degrees. Meaning it is objectively going to be more hydrophobic.

How Strong Are Graphene Coatings?

Graphene coatings are hard but flexible.

“At a molecular level, it is 200 times stronger than steel, yet six times lighter and flexible.”[8] Graphene, if layered enough, has been proved to stop bullets and absorb twice as much impact as Kevlar.[9] Does this mean you can ride around like batman in your vehicle and not worry about bullets? No, you are not batman.

Your vehicle will not have the thickness required to achieve such results. However what graphene-based coatings on vehicles have achieved is a hardness of 9 on the Mohs Hardness scale.

If you are unfamiliar with this scale, it was created in 1812 by German scientist Friedrich Mohs.[10] It is a way to classify minerals based on their hardness. Talc being the softest with a rank of 1 and diamond being the hardest with a rank of 10. Your smartphone has a hardness of around a 5 or a 6 for comparison. This is why companies will try to sell you a screen protector with a hardness of 9.

Now back to vehicles, ceramic coatings typically never got above a 9. However, because graphene-based coatings are so strong yet flexible for the first time we have achieved a hardness level of 9. The coating has to be flexible because as your paint is warmed in the summer sun it expands. Think about tectonic plates under the earth. As the constantly expand and contract the ground eventually gives away and you have earthquakes. The same is true of the protection on your paint. It has to be flexible enough to handle the expansion and contractions of the paint underneath without being so rigid that it cracks. Thankfully with the addition of graphene-based coatings, we can apply something that is stronger but will not crack due to its flexibility. This helps with not only the longevity but also it is going to make your paint harder to scratch. Now again it is not bullet proof so you can still scratch your paint, it is just going to be more scratch resistant than your traditional ceramic coatings.

How Do Graphene Coatings Maintain a Glossy, Mirror-Like Finish on Your Car?

The objective gloss readings are marginal between traditional ceramic coatings and graphene-based coatings. The bigger point though is you are not losing that incredible finish you get from a ceramic coating with a graphene-based coating. As long as the proper time and technique goes into preparing the vehicle the results will be stunning.

Conclusion

With anything new there will always be skepticism that comes with it. However, after hours and hours of listening to chemists and reading scholarly articles about graphene-based coatings, we here at Fort Worth Auto Detail are convinced it is the future of detailing. We are proud to be one the first and only options where you get a graphene coating for your vehicle. So, what are you waiting for? You deserve a graphene-based coating on your vehicle. Book today!

Sources

[1] https://www.nobelprize.org/prizes/physics/2010/press-release/ [2] IBID [3] https://ethoscarcare.com/pages/graphene-coating-technology [4] IBID [5] https://www.youtube.com/watch?v=Jevs_iIrzVI&t=3325s [6] https://ethoscarcare.com/pages/graphene-coating-technology [7] http://bit.ly/2XUwosi [8] https://ethoscarcare.com/pages/graphene-coating-technology [9] https://expandusceramics.com/qa/how-thick-does-graphene-need-to-be-to-stop-a-bullet.html [10] https://www.nps.gov/articles/mohs-hardness-scale.htm

[11] https://gloveboxdetail.com/blogs/news/graphene-vs-ceramic-coatings

[12] https://www.youtube.com/watch?v=Jevs_iIrzVI

[13] https://adamspolishes.com/pages/whats-the-difference-between-graphene-and-traditional-ceramic-coatings

[14] Eftekhari, A.; Garcia, H. (2017). “The Necessity of Structural Irregularities for the Chemical Applications of Graphene”. Materials Today Chemistry. 4: 1–16. doi:10.1016/j.mtchem.2017.02.003.

[15] https://drivedetailed.com/graphene-coating-for-cars-why-the-hype/